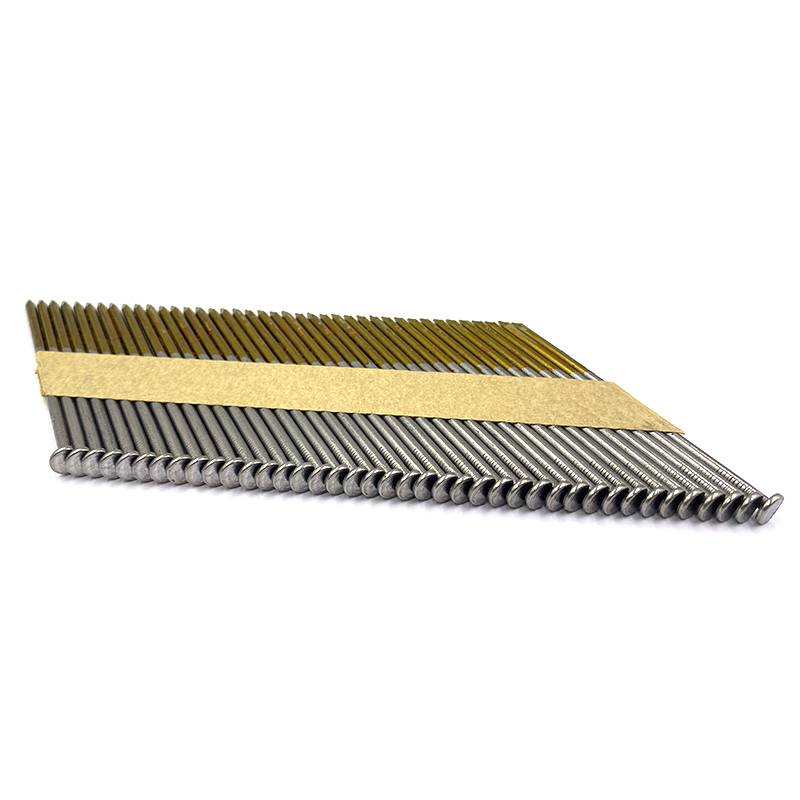

Here are some key advantages of using 34 degree paper collated framing nails in construction:

Ease of use

They come pre-assembled in paper strips so they can be loaded directly into a pneumatic nail gun for faster driving.

Controlled angle

The 34-degree tapered head slips easily under sheathing/siding/trim without dimpling for a clean look.

Withdrawal resistance

The angled head counters rotation, preventing nails from backing out over time under dynamic loads.

Penetration

Just the right angle penetrates wood efficiently without over-driving or under-driving nails.

Grip

Higher surface area of the head relative to shank improves holding power in material.

Concealability

Low profile design leaves nail heads nearly flush/hidden after driving.

Consistency

All nails identical for reliable performance shot after shot with a pneumatic tool.

Durability

Hardened carbon steel won’t bend or break under stress like under-spec framing nails.

Cost

Paper collated strips result in less wasted nails and higher productivity than using loose bulk.

So 34° collated framing nails deliver control, reliability and clean finishes that save time vs cut nails or staples.