Home » Posts tagged 'China 6025 fiber laser cutting machine'

Tag Archives: China 6025 fiber laser cutting machine

How can I determine the accuracy and precision of a fiber laser cutting machine?

The accuracy and precision of a fiber laser cutting machine are critical factors to consider when selecting a machine for your specific cutting requirements.

Here are some ways to determine the accuracy and precision of a fiber laser cutting machine:

Look for machine specifications: Machine specifications such as repeatability, positioning accuracy, and cutting accuracy can give you an idea of the machine’s precision. The manufacturer’s specifications should provide information on the tolerance levels that the machine can achieve.

Ask for cutting samples: Ask the manufacturer to provide cutting samples to test the machine’s accuracy and precision. This can give you a better idea of how well the machine can cut the materials you’ll be using.

Check for stability: A stable machine is essential for accurate and precise cutting. Check to see if the machine has a rigid structure and is designed to minimize vibrations during cutting.

Review customer feedback: Look for feedback from other customers who have used the machine to determine its accuracy and precision. This can be found on review websites, forums or by contacting the manufacturer for references.

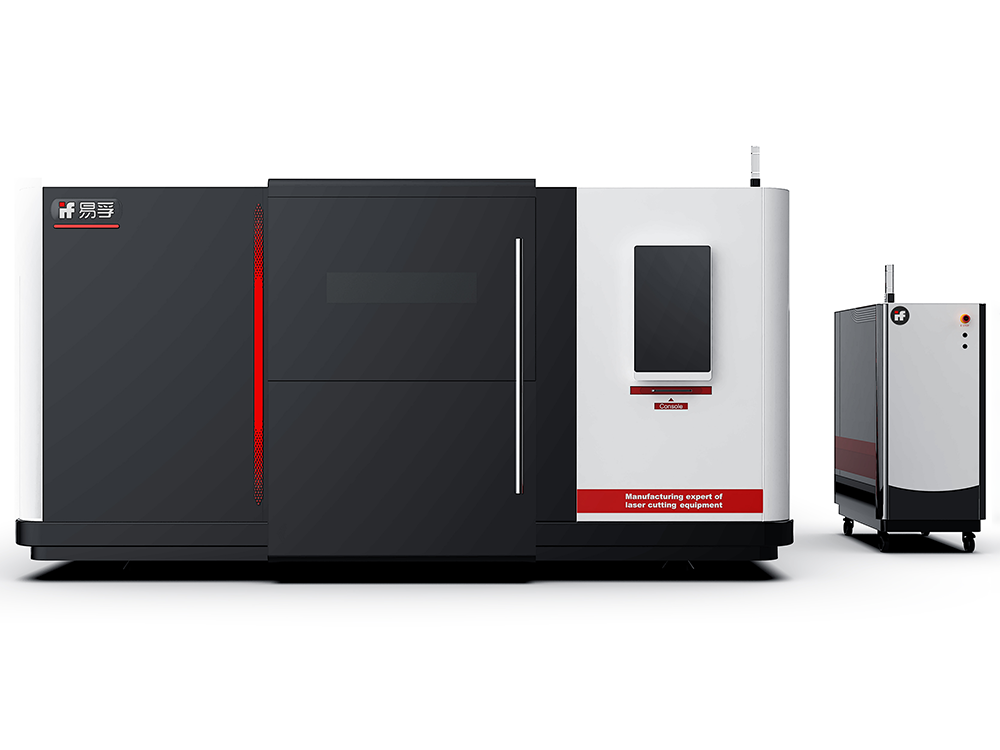

Consider the laser source: The laser source can have a significant impact on the accuracy and precision of a fiber laser cutting machine. China 6025 fiber laser cutting machine Look for machines with high-quality laser sources from reputable manufacturers.

Overall, the accuracy and precision of a fiber laser cutting machine depend on several factors, including machine specifications, cutting samples, stability, and laser source quality. It’s important to thoroughly research and test a machine before making a purchase to ensure it can meet your cutting requirements.

What are some common materials that fiber laser cutting machines can cut?

Fiber laser cutting machines are versatile industrial cutting tools that can cut a wide range of materials, including:

Metals: Fiber laser cutting machines can cut a variety of metals, including steel, aluminum, copper, brass, titanium, and more.

Plastics: They can also cut a variety of plastics, such as acrylic, polycarbonate, PVC, and more.

Wood: Fiber laser cutting machines can cut various types of wood, including plywood, MDF, and hardwoods.

Fabrics: They can cut fabrics, including cotton, silk, and polyester.

Composites: Composites such as carbon fiber, fiberglass, and Kevlar can also be cut using a fiber laser cutting machine.

Foam: Foam materials such as polyurethane foam, expanded polystyrene (EPS), and foam rubber can be cut using a fiber laser cutting machine.

Paper and cardboard: They can also cut paper and cardboard for packaging and other applications.

Overall, fiber laser cutting machines are capable of cutting a wide range of materials, making them a versatile tool for many industrial cutting applications. The specific materials that can be cut will depend on the power of the laser, the thickness of the material, and the specific cutting requirements.