What are the maintenance and inspection requirements for fire fighting foam equipment?

The maintenance and inspection requirements for fire fighting foam equipment may vary depending on the specific type of equipment and manufacturer recommendations.

However, here are some general considerations:

Regular Inspections: Conduct regular visual inspections of the equipment to check for any signs of damage, wear, or corrosion. Inspect hoses, nozzles, valves, and foam proportioning systems for proper functioning and cleanliness.

Functional Testing: Periodically test the foam equipment to ensure it is working correctly. This may include activating the foam proportioning system, testing the foam concentrate delivery system, and checking the operation of foam generators or nozzles.

Foam Concentrate Storage: If foam concentrate is stored on-site, ensure proper storage conditions as specified by the manufacturer. This may include maintaining appropriate temperature ranges, protecting from direct sunlight, and regularly checking for expiry dates.

Foam Concentrate Quality: Regularly check the quality of the foam concentrate to ensure it meets the required specifications. This may involve conducting tests to verify the concentration, viscosity, and other relevant parameters.

Training and Certification: Provide training to personnel responsible for operating and maintaining the foam equipment. Ensure they are familiar with the equipment’s operation, maintenance procedures, safety protocols, and any applicable regulations or standards. Keep records of training and certifications.

Documentation and Records: Maintain accurate records of maintenance activities, inspections, tests, repairs, and any modifications made to the foam equipment. This documentation can help track the equipment’s history, ensure compliance, and aid in troubleshooting or future maintenance.

Manufacturer Guidelines: Follow the manufacturer’s instructions and recommendations for maintenance, servicing, and inspection intervals specific to the equipment. Manufacturers often provide detailed guidelines and schedules tailored to their products.

Professional Servicing: Depending on the complexity of the foam equipment, it may be necessary to engage professional technicians or authorized service providers for more advanced maintenance and repair tasks. Follow the manufacturer’s guidelines regarding professional servicing.

It is important to note that the specific maintenance and inspection requirements may vary for different types of foam equipment (e.g., foam proportioning systems, foam generators) and regional regulations. It is recommended to refer to the equipment’s operation and maintenance manual or consult with the manufacturer or a qualified fire protection professional for detailed guidance based on your specific equipment.

How is fire fighting foam equipment tested and certified for effectiveness and safety?

Fire fighting foam equipment is tested and certified through a combination of industry standards, regulatory requirements, and independent testing organizations.

The testing and certification process typically involves the following steps:

Compliance with Standards: Fire fighting foam equipment is designed and manufactured to meet specific industry standards and regulatory requirements. These standards define performance criteria, construction guidelines, and safety considerations for foam equipment. Examples of widely recognized standards for fire fighting foam equipment include NFPA 11, UL 162, and EN 1568.

Laboratory Testing: Foam equipment manufacturers conduct extensive laboratory testing to evaluate the performance, functionality, and safety of their products. fire fighting foam equipment These tests often include assessments of foam generation, foam expansion, foam stability, proportioning accuracy, and compatibility with various foam concentrates.

Certification Bodies: Independent certification bodies evaluate fire fighting foam equipment to ensure compliance with applicable standards and regulations. These organizations verify that the equipment meets the required performance and safety criteria. Examples of well-known certification bodies include Underwriters Laboratories (UL), FM Approvals, and VdS.

Field Testing: In addition to laboratory testing, foam equipment may undergo field testing to assess its performance in real-world fire scenarios. Field testing may involve evaluating the equipment’s effectiveness in extinguishing fires, its compatibility with different types of flammable liquids, and its operational reliability under varying conditions.

Quality Management Systems: Manufacturers of fire fighting foam equipment often have quality management systems in place to ensure consistent product quality and adherence to standards. These systems involve rigorous inspections, process controls, and documentation to maintain quality throughout the manufacturing process.

Compliance Documentation: Once the foam equipment has successfully undergone testing and certification, the manufacturer provides documentation to support its compliance. This documentation may include test reports, certificates, user manuals, installation guidelines, and maintenance instructions.

It’s important to note that different regions and jurisdictions may have specific requirements for the testing and certification of fire fighting foam equipment. Authorities having jurisdiction (AHJs) enforce these requirements and may conduct their own inspections and tests to ensure compliance with local regulations.

When selecting fire fighting foam equipment, it is advisable to look for products that carry recognized certifications from reputable testing organizations. These certifications provide assurance that the equipment meets essential safety and performance standards.

Can the best wet wipes be used on different surfaces or only on the skin?

The best wet wipes can be used on a variety of surfaces, not just on the skin. While wet wipes are commonly associated with personal hygiene, there are specialized wipes available for different applications.

Here are some examples:

Personal Hygiene: Wet wipes designed for personal hygiene are primarily intended for use on the skin. They are commonly used for cleaning hands, face, and body when access to soap and water is limited. These wipes are typically gentle, moisturizing, and formulated to maintain the skin’s pH balance.

Baby Care: Wet wipes formulated specifically for baby care are suitable for use on delicate baby skin. They are designed to clean and moisturize the baby’s bottom during diaper changes. Baby wipes are generally gentle, hypoallergenic, and free from harsh chemicals that could irritate the baby’s skin.

Household Cleaning: There are wet wipes specifically designed for household cleaning purposes. These wipes are typically more robust and have stronger cleaning agents to tackle dirt, stains, and germs on various surfaces. They can be used to wipe down countertops, kitchen appliances, bathroom fixtures, and other household surfaces.

Electronics: Some wet wipes are specifically formulated for cleaning electronic devices and screens. These wipes are usually lint-free, non-abrasive, and safe for use on sensitive screens like smartphones, tablets, computer monitors, and televisions. They help remove fingerprints, smudges, and dust without causing damage.

Automotive: Wet wipes designed for automotive use can be used to clean and refresh the interior surfaces of vehicles. They are formulated to remove dirt, grease, stains, and spills from car upholstery, dashboard, steering wheel, and other surfaces. Automotive wet wipes often have a pleasant scent to help freshen the car’s interior.

It’s important to read the product labels and instructions to ensure that the wet wipes are suitable for the intended surface. best wet wipes Some wipes may be multi-purpose and safe for use on both skin and surfaces, while others may have specific recommendations or limitations. Always follow the manufacturer’s guidelines for optimal use and effectiveness.

What are the ingredients typically found in high-quality wet wipes?

High-quality wet wipes can vary in their specific formulations, but they generally contain a combination of the following ingredients:

Water: Water is the primary ingredient in wet wipes and serves as the solvent for other ingredients. It helps provide moisture and aids in the cleansing process.

Cleansing Agents: Wet wipes contain cleansing agents that help remove dirt, impurities, and oils from the skin or surfaces. These agents can include surfactants such as sodium lauryl sulfate or cocamidopropyl betaine.

Moisturizers: Many wet wipes feature moisturizing ingredients to help prevent dryness and maintain skin hydration. Common moisturizers found in wet wipes include glycerin, aloe vera, chamomile extract, or natural oils like jojoba oil or coconut oil.

Preservatives: Wet wipes often contain preservatives to prevent the growth of bacteria, fungi, and other microorganisms. Common preservatives used in wet wipes include phenoxyethanol, benzyl alcohol, or parabens.

Fragrances: Some wet wipes may have added fragrances to provide a pleasant scent. However, it’s important to note that fragrances can be potential allergens for some individuals, so fragrance-free options are also available.

pH Balancers: Wet wipes formulated for personal hygiene or baby care may include pH balancers to maintain the skin’s natural pH level. These balancers help protect the skin barrier and minimize irritation.

Mild Antiseptics: In certain wet wipes, mild antiseptics like benzalkonium chloride or alcohol may be included to help disinfect the skin or surfaces. These ingredients can provide additional cleansing and germ-fighting properties.

It’s important to read the product labels and check for any ingredients that may be of concern, especially if you have specific allergies or sensitivities. Different brands and types of wet wipes may have variations in their ingredients, so it’s advisable to choose products that align with your specific needs and preferences.

The Ultimate Guide to Selecting the Best wet wipes for face and Unleashing Their Advantages

Selecting the China best wet wipes for face manufacturer is crucial to ensure effective cleansing and maximize their advantages. Here’s an ultimate guide to help you choose the right wet wipes and unleash their benefits:

Skin Type: Consider your skin type when selecting wet wipes. Different wipes are formulated to address specific skin concerns. For example:

Dry or sensitive skin: Look for wipes that are gentle, fragrance-free, and enriched with moisturizing ingredients like aloe vera or chamomile.

Oily or acne-prone skin: Opt for wipes with oil-controlling properties, such as those containing salicylic acid or tea tree oil. These can help remove excess oil and unclog pores.

Combination or normal skin: Choose wipes that provide balanced cleansing and hydration without being too harsh or heavy.

Ingredients: Read the label and check the ingredients list. Avoid wipes that contain harsh chemicals, alcohol, or fragrance if you have sensitive skin. Look for wipes with natural or skin-friendly ingredients that nourish and soothe the skin.

Cleansing Power: Ensure that the wet wipes you choose have effective cleansing power. Look for wipes that can remove dirt, makeup, and impurities thoroughly without excessive rubbing or tugging on the skin. Consider wipes with textured surfaces for gentle exfoliation if desired.

Moisture and Hydration: Wet wipes should provide sufficient moisture and hydration to prevent dryness or tightness. Look for wipes with moisturizing properties, such as hyaluronic acid or glycerin, which help to keep the skin hydrated and supple.

pH Balance: Opt for wet wipes that are pH-balanced to match the natural pH of your skin. This helps maintain the skin’s protective barrier and prevents irritation or disruption of the skin’s natural balance.

Dermatologically Tested: Choose wet wipes that have been dermatologically tested and proven to be safe for use on the face. These wipes have undergone rigorous testing to ensure their compatibility with the skin and minimize the risk of adverse reactions.

Package Design: Consider the packaging design of the wet wipes. Look for resealable packs or individually wrapped wipes to prevent them from drying out and maintain their freshness.

Reviews and Recommendations: Check customer reviews and seek recommendations from trusted sources or skincare professionals. Real-life experiences can provide valuable insights into the effectiveness and compatibility of different wet wipes.

Advantages of Using Wet Wipes for the Face:

Convenience: Wet wipes are incredibly convenient for quick and on-the-go cleansing. They eliminate the need for water, cleansers, or towels, making them ideal for travel, gym sessions, or refreshing during the day.

Makeup Removal: Wet wipes are efficient at removing makeup, including waterproof products. They can save time and effort in your skincare routine, allowing for easy makeup removal without the need for additional cleansing steps.

Freshness and Hygiene: Wet wipes provide a refreshing and hygienic solution to cleanse the face, especially in situations where washing facilities are limited or unavailable. They help remove sweat, oil, and impurities, leaving the skin feeling clean and refreshed.

Portability: Wet wipes are portable and easy to carry in your bag or purse, making them convenient for on-the-go use. They offer a quick and hassle-free option to freshen up during the day or while traveling.

Versatility: Wet wipes can serve multiple purposes beyond facial cleansing. They can be used to wipe hands, neck, or other parts of the body when necessary. Some wipes are specifically designed for specific skin concerns, such as oil control or acne treatment.

Remember to follow the instructions provided by the manufacturer when using wet wipes on the face. While convenient, they should not replace your regular skincare routine, especially when it comes to thorough cleansing and moisturizing.

How do cloth diapers differ from disposable diapers in terms of usage and maintenance?

Cloth diapers and disposable diapers differ in several aspects, including usage and maintenance.

Here are some key differences:

Reusability: Cloth diapers are reusable, while disposable diapers are intended for single-use. Cloth diapers can be washed and reused multiple times, whereas disposable diapers are discarded after each use.

Cost: Cloth diapers have a higher upfront cost since they require an initial investment to purchase the diapers and necessary accessories like inserts and covers. However, over time, cloth diapers can be more cost-effective as they can be reused multiple times, reducing the need for continuous purchases of disposable diapers.

Environmental Impact: Cloth diapers are often considered more environmentally friendly since they generate less waste. They can be washed and reused, reducing the amount of diaper waste sent to landfills. On the other hand, disposable diapers contribute significantly to landfill waste due to their single-use nature.

Absorbency and Leakage: Disposable diapers generally have higher absorbency compared to cloth diapers. They often contain superabsorbent polymers that can hold larger amounts of liquid. This can result in fewer leaks and a drier feel for the baby. Cloth diapers may require more frequent changes to maintain dryness and prevent leaks.

Convenience: Disposable diapers are generally considered more convenient since they are ready to use and require no washing or maintenance. Cloth diapers, on the other hand, require regular washing and drying, which can add to the caregiver’s workload. However, some caregivers find the convenience of cloth diapers worth the extra effort due to their long-term benefits.

Fit and Adjustability: Cloth diapers offer more customization options in terms of fit and adjustability. They often come with adjustable snaps or Velcro closures and multiple sizing options, allowing for a better fit as the baby grows. Disposable diapers, while available in different sizes, may not provide the same level of customization for fit.

Chemicals and Sensitivity: Disposable diapers may contain chemicals such as dyes, fragrances, and absorbent gels, which can potentially cause skin irritation or allergies in some babies. Cloth diapers, particularly those made from natural fibers, may be a preferred choice for babies with sensitive skin.

Laundry Requirements: Cloth diapers require regular washing and drying, which adds to the laundry routine. They may need pre-rinsing, soaking, or specific washing instructions to maintain their absorbency and longevity. Disposable diapers, on the other hand, eliminate the need for diaper laundry.

It’s important to note that both cloth diapers and disposable diapers have their advantages and disadvantages. China diaper manufacturing The choice between them depends on individual preferences, lifestyle, budget, and environmental considerations. Some parents even opt for a combination of both, using cloth diapers at home and disposable diapers when traveling or during certain situations.

How has the design and functionality of diapers evolved over the years?

The design and functionality of diapers have evolved significantly over the years, driven by advancements in materials, technology, and the understanding of baby care needs.

Here are some notable changes:

Absorbency: Diapers have become more effective in absorbing and containing moisture. The introduction of superabsorbent polymers (SAP) revolutionized diaper absorbency. SAP can absorb and lock away large amounts of liquid, keeping the baby’s skin dry and reducing the risk of leaks.

Shape and Fit: Diapers have been redesigned to provide a better fit and increased comfort for babies. They now feature elasticized waistbands, leg cuffs, and stretchable panels, allowing for a snug and secure fit that adapts to the baby’s movements.

Closure Systems: Diapers have transitioned from traditional pins to more convenient closure systems. Adhesive tapes or hook-and-loop fasteners (such as Velcro) are commonly used to secure the diaper in place, offering a more user-friendly and adjustable closure system.

Breathability: Improved breathability is a key feature in modern diapers. Breathable materials and designs promote air circulation, reducing the risk of skin irritation and enabling better temperature regulation.

Wetness Indicators: Many disposable diapers now include wetness indicators. These color-changing strips or patterns on the diaper’s exterior provide a visual cue to caregivers, indicating when the diaper needs changing.

Size Options: Diapers are available in a range of sizes to accommodate the changing needs of babies as they grow. This allows for a better fit and improved leakage prevention.

Eco-Friendly Options: With growing environmental concerns, eco-friendly diaper options have gained popularity. These diapers are often made from sustainable materials and incorporate biodegradable or compostable components, reducing their impact on the environment.

Diaper Pants: Diaper pants, also known as pull-up diapers, have become popular alternatives to traditional adhesive-tape diapers. They are designed to be pulled up and down like underwear, making diaper changes easier for active and older babies.

Specialized Diapers: Diapers have been developed to address specific needs, such as overnight diapers for extended protection during sleep, swim diapers for use in water, and diapers designed for premature infants or babies with sensitive skin.

Smart Diapers: With the rise of wearable technology, smart diapers have emerged. These diapers include sensors that can monitor a baby’s urine output, temperature, or even detect possible urinary tract infections. This technology aims to provide caregivers with insights into their baby’s health and well-being.

Overall, the design and functionality of diapers have evolved to prioritize comfort, convenience, and performance while incorporating eco-friendly and innovative features to meet the changing needs of both babies and caregivers.

What are the typical applications or industries where strength testing machines are used?

Strength testing machines find applications in various industries and sectors where the mechanical properties and strength of materials or components need to be evaluated.

Here are some typical applications and industries where strength testing machines are used:

Manufacturing and Engineering: Strength testing machines are extensively used in the manufacturing and engineering industries to assess the strength, durability, and performance of materials, components, and finished products. This includes testing of metals, alloys, plastics, ceramics, composites, and other materials used in industries such as automotive, aerospace, construction, and consumer goods.

Quality Control and Assurance: Strength testing machines play a crucial role in quality control and assurance processes. They help ensure that materials and products meet specified standards, regulations, and customer requirements. By performing strength tests, manufacturers can identify defects, weaknesses, or inconsistencies in materials or finished products.

Research and Development: Strength testing machines are utilized in research and development activities to investigate new materials, develop improved manufacturing processes, and assess the performance of prototypes or experimental components. Researchers can study the mechanical behavior, fatigue resistance, and other characteristics of materials under different conditions.

Building and Construction: In the construction industry, strength testing machines are used to evaluate the strength and load-bearing capacity of building materials such as concrete, cement, asphalt, aggregates, and structural elements. These tests help ensure structural integrity and compliance with building codes and standards.

Pharmaceutical and Medical Devices: Strength testing machines are employed in the pharmaceutical and medical device industries to assess the mechanical strength and integrity of drug delivery systems, packaging materials, medical implants, syringes, and other components. These tests help ensure product safety and reliability.

Textile and Fabrics: Strength testing machines are utilized to measure the tensile strength, tear resistance, and other mechanical properties of textiles and fabrics. These tests are essential in the textile industry for quality control, product development, and compliance with industry standards.

Plastics and Polymers: Strength testing machines are employed in the plastics and polymer industry to evaluate the mechanical properties, including tensile strength, flexural strength, impact resistance, and elongation at break. These tests assist in material selection, product design, and quality control.

Packaging and Material Handling: Strength testing machines are used to assess the strength and integrity of packaging materials, such as plastics, cardboard, paperboard, and corrugated containers. These tests ensure that packaging can withstand transportation, storage, and handling stresses without failure.

Education and Research Institutes: Strength testing machines are essential equipment in educational institutions and research laboratories for teaching purposes, conducting experiments, and studying material properties. They help students and researchers understand the behavior of materials under different loading conditions.

Consumer Product Testing: Strength testing machines are employed to evaluate the durability and performance of various consumer products, such as furniture, appliances, electronics, toys, and sports equipment. These tests help manufacturers ensure that their products can withstand typical usage and meet safety standards.

These are just a few examples of the broad range of applications and industries where strength testing machines are used. The specific requirements and test methods vary depending on the industry and the materials being evaluated.

What are the safety precautions and guidelines to follow when operating a strength testing machine?

When operating a strength testing machine, it is crucial to follow safety precautions and guidelines to ensure the well-being of operators and the proper functioning of the equipment.

Here are some general safety precautions to consider:

Familiarize Yourself with the Machine: Read and understand the manufacturer’s operating manual and instructions before using the strength testing machine. Familiarize yourself with its components, controls, and safety features.

Personal Protective Equipment (PPE): Wear appropriate personal protective equipment, such as safety glasses, gloves, and protective clothing, strength testing machine as recommended by the manufacturer or safety guidelines.

Training and Competence: Ensure that operators are adequately trained and competent in operating the strength testing machine. Training should cover proper machine operation, understanding of testing procedures, and safety protocols.

Equipment Inspection: Regularly inspect the strength testing machine for any signs of damage, wear, or malfunction. Do not operate the machine if any abnormalities are detected. Report any issues to the relevant personnel or supervisor.

Workspace Safety: Maintain a clean and organized workspace around the strength testing machine. Keep the area free of clutter, obstructions, and trip hazards. Ensure proper lighting and ventilation in the testing area.

Load Capacity and Overloading: Adhere to the recommended load capacity of the strength testing machine. Avoid overloading the machine, as it can lead to equipment failure, accidents, or injury.

Secure Sample Fixturing: Properly secure and align the sample or specimen being tested in the testing machine. Follow the manufacturer’s instructions for sample preparation and fixturing to ensure accurate and safe testing.

Emergency Stop and Shutdown: Familiarize yourself with the emergency stop and shutdown procedures of the strength testing machine. Know the location and operation of emergency buttons or switches to immediately halt the testing process if necessary.

Safe Distance: Maintain a safe distance from the strength testing machine during operation to avoid potential injury from moving parts, sample failure, or unexpected machine behavior.

Record Keeping: Maintain accurate records of testing procedures, results, and any relevant observations. Proper documentation helps in traceability, analysis, and monitoring of the testing process.

It’s important to note that these are general safety precautions, and specific safety guidelines may vary depending on the type and model of the strength testing machine. Always refer to the manufacturer’s instructions and any applicable safety regulations or guidelines to ensure safe operation.

The Ultimate Guide to Choosing the Right 18 Ga Brad Nail for Your Application

Here are some key factors to consider when choosing the right 18 ga brad nail 1 inch for your application:

Length

Will depend on material thickness being joined. For thinner materials, use shorter brads (1/2″, 3/4″). Thicker items require longer (1-1/4″, 1-1/2″, 1-3/4″).

Head style

Standard round heads are common but narrow crown/tapered heads hide better. Magnetic heads are ideal for paneling work.

Shank type

Finely threaded brads provide maximum holding power. Coarser threads are quicker but can split wood. Smooth shanks slip.

Material

Steel brads are standard and economical. Stainless resists corrosion. Aluminum heads won’t rust but shanks can bend easier than steel.

Coating

Exteriors coated in chrome, rust-inhibiting paint or zinc plating resist moisture and corrosion better than uncoated nails.

Application

Consider joint type (butting or binding), forces/stress points, material thickness and moisture level.

Quantity

Bulk packaging offers best cost per unit for repetitive tasks. Blister packs are convenient for small jobs.

Choosing the correctly sized, tailored 18g brad will result in a secure, long-lasting connection between materials for various indoor or outdoor applications.

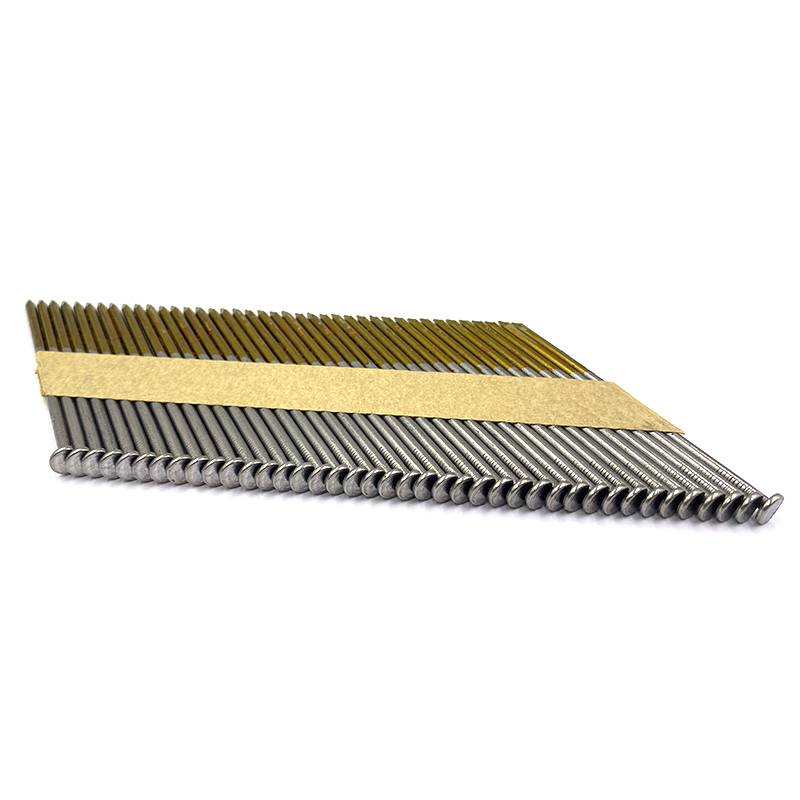

What are the advantages of using 34 degree paper collated framing nails?

Here are some key advantages of using 34 degree paper collated framing nails in construction:

Ease of use

They come pre-assembled in paper strips so they can be loaded directly into a pneumatic nail gun for faster driving.

Controlled angle

The 34-degree tapered head slips easily under sheathing/siding/trim without dimpling for a clean look.

Withdrawal resistance

The angled head counters rotation, preventing nails from backing out over time under dynamic loads.

Penetration

Just the right angle penetrates wood efficiently without over-driving or under-driving nails.

Grip

Higher surface area of the head relative to shank improves holding power in material.

Concealability

Low profile design leaves nail heads nearly flush/hidden after driving.

Consistency

All nails identical for reliable performance shot after shot with a pneumatic tool.

Durability

Hardened carbon steel won’t bend or break under stress like under-spec framing nails.

Cost

Paper collated strips result in less wasted nails and higher productivity than using loose bulk.

So 34° collated framing nails deliver control, reliability and clean finishes that save time vs cut nails or staples.

What are some factors to consider when selecting a high-performance butterfly valve for a specific application?

A high-performance butterfly valve is a type of valve commonly used in industrial applications to control the flow of fluids. It is designed to provide efficient and reliable performance in demanding conditions.

Here are some key features and characteristics of high-performance butterfly valves:

Construction: High-performance butterfly valves are typically constructed with a metal body, such as stainless steel or ductile iron, which provides durability and resistance to corrosion. The valve disc or “butterfly” is mounted on a shaft and can be made of metal or other materials depending on the application requirements.

Sealing Mechanism: These valves employ a resilient or metal-to-metal sealing mechanism. Resilient seals, often made of materials like EPDM or PTFE, provide tight sealing and are suitable for a wide range of fluids. Metal-to-metal seals, such as graphite or metal seats, are used for higher temperature or more aggressive applications.

Bi-Directional Shut-off: High-performance butterfly valves are designed to provide tight shut-off in both flow directions. This ensures that they can effectively stop the flow of fluid in either direction, preventing leakage and maintaining system integrity.

High Flow Capacity: These valves are known for their large flow capacity and low pressure drop. The streamlined disc and body design allow for efficient fluid passage, minimizing flow restrictions and maximizing flow rates.

Temperature and Pressure Ratings: High-performance butterfly valves are designed to handle a wide range of temperatures and pressures. The specific temperature and pressure ratings depend on the construction materials, seal type, and design specifications.

Actuation Options: Butterfly valves can be manually operated or automated using various actuation methods. Actuators, such as electric, pneumatic, or hydraulic actuators, can be attached to the valve to enable remote control and automation of the valve operation.

Versatility: High-performance butterfly valves are suitable for a wide range of applications across industries, including oil and gas, chemical processing, water treatment, power generation, and HVAC systems. They are often used for both on/off and throttling control applications.

Reliability and Maintenance: High-performance butterfly valves are designed for long service life and minimal maintenance requirements. Properly selected and maintained valves can provide reliable operation and withstand demanding conditions.

It’s important to consider the specific requirements of your application, such as fluid type, temperature, pressure, and flow characteristics when selecting a high-performance butterfly valve. Consulting with valve manufacturers or industry professionals can help determine the most suitable valve for your specific needs.

When selecting a high-performance butterfly valve for a specific application, several factors should be considered to ensure optimal performance and suitability.

Here are some key factors to consider:

Application Requirements: Understand the specific requirements of your application, including the type of fluid (liquid or gas), temperature range, pressure range, flow characteristics (such as velocity and turbulence), and any special considerations like corrosiveness or abrasiveness. This information will help determine the appropriate valve materials, seals, and design features.

Valve Size and Pressure Rating: Consider the required valve size based on the pipe diameter and flow rate of the system. Additionally, take into account the pressure rating needed to handle the maximum operating pressure without compromising performance or safety. Ensure that the selected valve meets or exceeds the required size and pressure ratings.

Construction Materials: Evaluate the compatibility of the valve materials with the fluid being handled and the surrounding environment. Consider factors such as corrosion resistance, temperature resistance, and mechanical strength. high performance butterfly valve Common materials include stainless steel, carbon steel, ductile iron, and various alloys. Select materials that can withstand the specific conditions of your application.

Sealing Mechanism: Determine the appropriate sealing mechanism based on the fluid characteristics and the desired level of sealing performance. Resilient seals, such as EPDM or PTFE, are commonly used for general applications. Metal seals or laminated seals may be required for high-temperature or aggressive fluid applications. Consider factors like sealing performance, maintenance requirements, and compatibility with the fluid.

Actuation Method: Decide whether manual operation or automated actuation is required for your application. Consider factors such as the need for remote control, speed of operation, and integration with control systems. Different actuation methods, such as electric, pneumatic, or hydraulic actuators, have their own advantages and considerations.

Flow Control Requirements: Determine if the valve will be used for on/off control or throttling control. Some high-performance butterfly valves are designed specifically for precise flow modulation, while others are better suited for simple open/close applications. Consider the flow characteristics of the fluid and the desired level of control.

Standards and Certifications: Ensure that the selected valve complies with relevant industry standards and certifications to guarantee quality, performance, and safety. Look for certifications such as API, ISO, ANSI, or specific industry standards applicable to your application.

Manufacturer and Supplier Reputation: Consider the reputation and track record of the valve manufacturer and supplier. Choose reliable and reputable companies known for producing high-quality valves and providing excellent customer support.

By carefully considering these factors, you can select a high-performance butterfly valve that meets the specific requirements of your application, ensuring efficient and reliable operation. Consulting with valve manufacturers or industry experts can provide valuable guidance in the selection process.

What are some common brands or manufacturers of 21-degree galvanized framing nails?

There are several reputable brands and manufacturers that produce 21-degree galvanized framing nails.

Here are some commonly known brands in the construction industry:

Bostitch: Bostitch is a well-known brand that offers a wide range of fastening solutions, including 21-degree galvanized framing nails. They are recognized for their quality and reliability in construction applications.

Grip-Rite: Grip-Rite is a popular brand that manufactures a variety of fasteners, including galvanized framing nails. They offer a range of sizes and lengths suitable for different framing needs.

Paslode: Paslode is a trusted manufacturer of fastening systems and tools. They produce galvanized framing nails compatible with their line of 21-degree pneumatic nailers.

Senco: Senco is a renowned brand in the construction industry, known for its high-quality fasteners and pneumatic tools. They offer a selection of 21-degree galvanized framing nails for use with their nailers.

Simpson Strong-Tie: Simpson Strong-Tie is primarily known for its structural connectors and fastening systems. They also produce galvanized framing nails that meet industry standards.

DeWalt: DeWalt, a well-established brand in the power tool market, also offers a range of fasteners, including 21-degree galvanized framing nails. Their nails are designed to work seamlessly with their compatible nailers.

It’s important to note that availability of specific brands and manufacturers may vary depending on your location and the suppliers in your area. When purchasing framing nails, consider factors such as quality, compatibility with your nail gun, and adherence to industry standards. It’s often beneficial to consult with local construction professionals or visit reputable hardware stores for guidance on selecting the right brand and type of framing nails for your specific project.

What are some industry standards that I should look for when purchasing framing nails?

When purchasing framing nails, it’s important to look for industry standards that ensure the quality, performance, and compatibility of the nails.

Here are some key standards to consider:

ASTM F1667: This standard, published by the American Society for Testing and Materials (ASTM), specifies the requirements for nails used in general construction and specifically addresses common nails, box nails, and other types of nails. It covers dimensions, 21 degree galvanized framing nails materials, testing procedures, and other performance characteristics.

ICC-ES AC233: The International Code Council Evaluation Service (ICC-ES) provides evaluation reports that assess the performance of construction products. ICC-ES AC233 specifically evaluates the corrosion resistance of fasteners, including nails, in treated wood products. Look for framing nails that comply with or are certified by ICC-ES AC233 to ensure durability and resistance to corrosion.

National Nail: National Nail is an organization that provides certification for nails used in construction. Their certification ensures that the nails meet specific quality and performance standards, including dimensional requirements and corrosion resistance. Look for framing nails with National Nail certification to ensure reliability and adherence to industry standards.

Collation Angle: The collation angle refers to the angle at which the nails are held together in nail strips or coils. For 21-degree galvanized framing nails, ensure that the collation angle matches the specifications recommended by the nail gun or pneumatic nailer you intend to use. This ensures proper feeding and compatibility.

Building Codes: Check the building codes and regulations in your jurisdiction. Local building codes often specify the types of fasteners, including nails, that are approved for specific construction applications. Compliance with building codes ensures that the framing nails meet the required standards for structural integrity and safety.

When purchasing framing nails, look for products that explicitly state compliance with relevant standards and certifications. This information is typically provided by the manufacturer or indicated on the product packaging. Consulting with local construction professionals or suppliers can also provide valuable guidance on selecting framing nails that meet the necessary industry standards for your specific project.

What are some of the advantages of using a vane pump over an axial piston pump?

While both vane pumps and axial piston pumps have their advantages and disadvantages, there are some specific advantages to using a vane pump over an axial piston pump.

Here are a few advantages of vane pumps:

Lower cost: Vane pumps are generally less expensive than axial piston pumps, which can make them a more attractive option for applications where cost is a primary concern.

Quieter operation: Vane pumps tend to be quieter in operation than axial piston pumps, which can be beneficial in applications where noise levels need to be kept to a minimum.

Simpler design: Vane pumps have a simpler design than axial piston pumps, with fewer moving parts. This can make them easier to maintain and repair.

Self-priming: Vane pumps are generally self-priming, which means they can handle air or gas in the hydraulic system without losing their prime. This can be beneficial in applications where the hydraulic system is exposed to air or gas.

High flow rate: Vane pumps can have a high flow rate, making them suitable for applications where a large volume of hydraulic fluid needs to be moved quickly.

It’s important to note that the specific advantages of vane pumps over axial piston pumps may vary depending on the specific application. China delphi equipment manufacturers It’s always a good idea to carefully consider the requirements of the application and consult with hydraulic system experts to determine the best pump for the job.

How do I determine the flow rate needed for my specific application?

Determining the flow rate needed for a specific hydraulic application requires careful consideration of several factors.

Here are some steps you can take to determine the flow rate needed for your application:

Determine the maximum operating pressure: The maximum operating pressure is the highest pressure the hydraulic system will need to generate. This information is typically provided by the manufacturer of the hydraulic equipment or machinery.

Calculate the minimum flow rate: The minimum flow rate is the amount of hydraulic fluid needed to operate the hydraulic system. This information is also typically provided by the manufacturer of the hydraulic equipment or machinery.

Consider the duty cycle: The duty cycle is the percentage of time the hydraulic system will be operating under normal conditions. This information can be used to calculate the average flow rate needed for the application.

Determine the size of the hydraulic components: The size of the hydraulic components, such as cylinders, valves, and motors, can also impact the flow rate needed for the application. The manufacturer of the hydraulic components can provide information on the flow rate required for optimal performance.

Factor in any special requirements: Some applications may have special requirements, such as the need for high-speed operation or the use of special fluids. These requirements can impact the flow rate needed for the application.

Once you have gathered this information, you can use it to calculate the flow rate needed for your specific application. It’s always a good idea to consult with hydraulic system experts to ensure that you are selecting the right pump and components for your application.